Welcome to the first installment of an on-going series called “Know Your Foam”. These posts will appear on a regular basis, each one a [moderately] deep dive into a specific foam topic. We’re starting with polyethylene foam, which has been an industry giant for decades.

Check back in a few weeks for our feature on polyurethane foam!

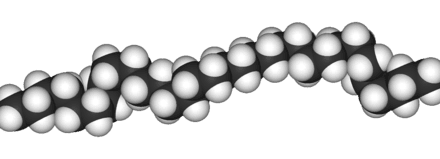

Polyethylene foam [Expanded Polyethylene, or EPE] is created when polyethylene [either LDPE or HDPE] is combined with a blowing agent.

Polyethylene is the most common type of plastic in use on the planet, despite its discovery being an accident [twice!]. Originally discovered by Hans von Pechmann in 1898, and rediscovered by Eric Fawcett and Reginald Gibson in 1933, it was first put into use in 1939 as insulation for coaxial cables used in radar sets. The 1970s saw polyethylene foam hit the scene, and it has been a growth market ever since. At almost $6B annually, polyethylene foam represents approximately 15% of the PE market by dollars sold.

Polyethylene foam is a closed-cell foam has a number of outstanding characteristics, including water resistance, shock and vibration absorption, flexibility, and tear resistance. In addition, it is lightweight and does not create dust. Thanks to these qualities, it has numerous uses, most commonly packaging, shipping, insulation, buoyancy, and device protection.

One common variant to standard EPE Foam is “Polylam”, or laminated polyethylene foam. Created through either heat lamination or adhesive lamination, the process offers a cost effective way to enhance the characteristics of the foam. Some examples include improving moisture resistance, adding an adhesive [pressure-sensitive adhesive, or PSA foam], or adding color / color contrasts.

In 2024, environmental concerns are more vital than ever. With that in mind, it is important that all foam products are recycled whenever possible, and otherwise disposed of properly. A key advantage of EPE foam is its durability, which means it can be reused.

In addition, EPE foam is a very lightweight yet ruggedly protective material for product packaging, which can reduce CO2 emissions during shipping.

All Foam Products offers a wide range of EPE foams, including but not limited to:

- Low-Density PE [LDPE]

- Medium-Density PE[MDPE]

- High-Density PE [HDPE]

- Cross-linked PE

- Polylaminate [Polylam]

We also offer a wide range of value-added services!